A PVC Twin Screw Extruder is a specialized machine designed for the extrusion process, where raw PVC materials are melted, mixed, and formed into various products such as pipes, films, and medical tubes. Utilizing two intermeshing screws, this type of extruder ensures efficient mixing and consistent quality of the output material, making it a cornerstone in the plastic manufacturing industry.

Twin screw compounding extruders, like those offered by Rajoo Bausano, are engineered to handle complex extrusion processes with precision and efficiency. The twin screws rotate in sync, providing superior mixing and better temperature control compared to single screw extruders. This technology is essential for applications requiring high levels of dispersion and uniformity, such as medical tubing and blood pouches.

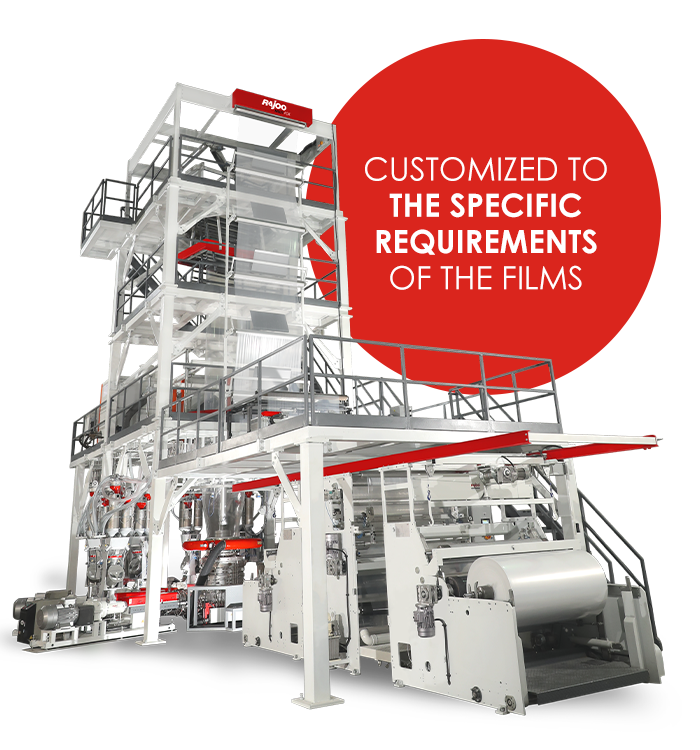

As one of the leading twin screw extruder manufacturers in India, Rajoo Bausano combines cutting-edge technology with unparalleled expertise. Our commitment to innovation and quality ensures that our machines meet the highest industry standards, providing our clients with reliable and efficient solutions for their extrusion needs.

Our twin screw PVC extruders are designed for maximum productivity, with outputs up to 130kg/hr.

The twin screw mechanism ensures thorough mixing and consistent material properties.

Suitable for a wide range of applications, from medical tubes to PVC films.

Features like the conical triple jaws and adjustment jack make cleaning and maintenance quick and hassle-free.

Built with durability in mind, ensuring long-term operation with minimal downtime.