Ensures smooth operation and reduces mechanical stress, extending the machine's lifespan.

Guarantees high production rates and excellent thermal and plastification stability.

The die head is connected via conical triple jaws, facilitating easy and quick opening and cleaning.

Capable of achieving outputs up to 130kg/hr, making it ideal for large-scale production.

Provides efficient cooling, essential for maintaining product quality.

Ensures accurate and noise-free operation, enhancing the work environment.

Extrusion of tubes with an outer diameter up to 30mm, used for various medical applications.

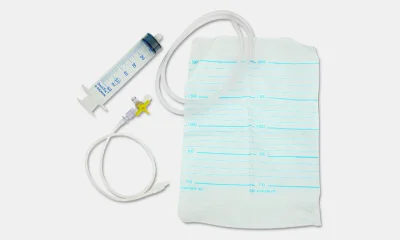

Production of tubular films for blood pouches, with widths ranging from 80mm to 400mm.

Manufacturing high-quality PVC pipes for various industrial uses.